The Appliance Humidity Crisis: How Steam and Moisture From Your Kitchen and Laundry Are Silently Destroying Your Home’s Electronics and What Chiliwack Homeowners Can Do

Ever wondered why your expensive kitchen appliances keep breaking down despite proper maintenance, or why that new dishwasher already needs repairs after just two years? The hidden culprit destroying your home’s valuable electronics isn’t wear and tear—it’s the silent, systematic attack of humidity and steam that most Chiliwack homeowners never see coming until it’s too late.Picture this scenario that’s becoming increasingly common across Chilliwack: You’re preparing dinner on a typical Fraser Valley evening when steam rises from boiling pasta, your dishwasher releases a cloud of moisture through its side vents, and the microwave above your stove quietly channels hot air upward into your cabinets. Meanwhile, in your laundry room, the dryer expels humid air while your washing machine adds its own contribution to the moisture load. What seems like normal household activity is actually creating a perfect storm of conditions that systematically destroy electronic components, corrode metal parts, and reduce appliance lifespans by years.  The unique climate challenges facing Chiliwack homeowners make this humidity crisis particularly severe. Our Fraser Valley location combines persistent moisture from Pacific weather systems with dramatic seasonal temperature fluctuations that stress appliance seals and gaskets. Unlike drier interior regions or more stable coastal areas, Chilliwack experiences rapid humidity changes that force home appliances to work harder while simultaneously exposing them to corrosive conditions that manufacturers rarely account for in their design specifications.Understanding the scope of appliance humidity damage prevention in Chilliwack requires recognizing that modern homes create more moisture than ever before, while energy-efficient construction traps that humidity inside where it can cause extensive damage. The financial implications extend far beyond simple repair costs, encompassing energy efficiency losses, premature replacement expenses, and potential property damage from water leaks and electrical failures that often manifest as mysterious performance issues long before visible damage appears.

The unique climate challenges facing Chiliwack homeowners make this humidity crisis particularly severe. Our Fraser Valley location combines persistent moisture from Pacific weather systems with dramatic seasonal temperature fluctuations that stress appliance seals and gaskets. Unlike drier interior regions or more stable coastal areas, Chilliwack experiences rapid humidity changes that force home appliances to work harder while simultaneously exposing them to corrosive conditions that manufacturers rarely account for in their design specifications.Understanding the scope of appliance humidity damage prevention in Chilliwack requires recognizing that modern homes create more moisture than ever before, while energy-efficient construction traps that humidity inside where it can cause extensive damage. The financial implications extend far beyond simple repair costs, encompassing energy efficiency losses, premature replacement expenses, and potential property damage from water leaks and electrical failures that often manifest as mysterious performance issues long before visible damage appears.

Key Outtakes:

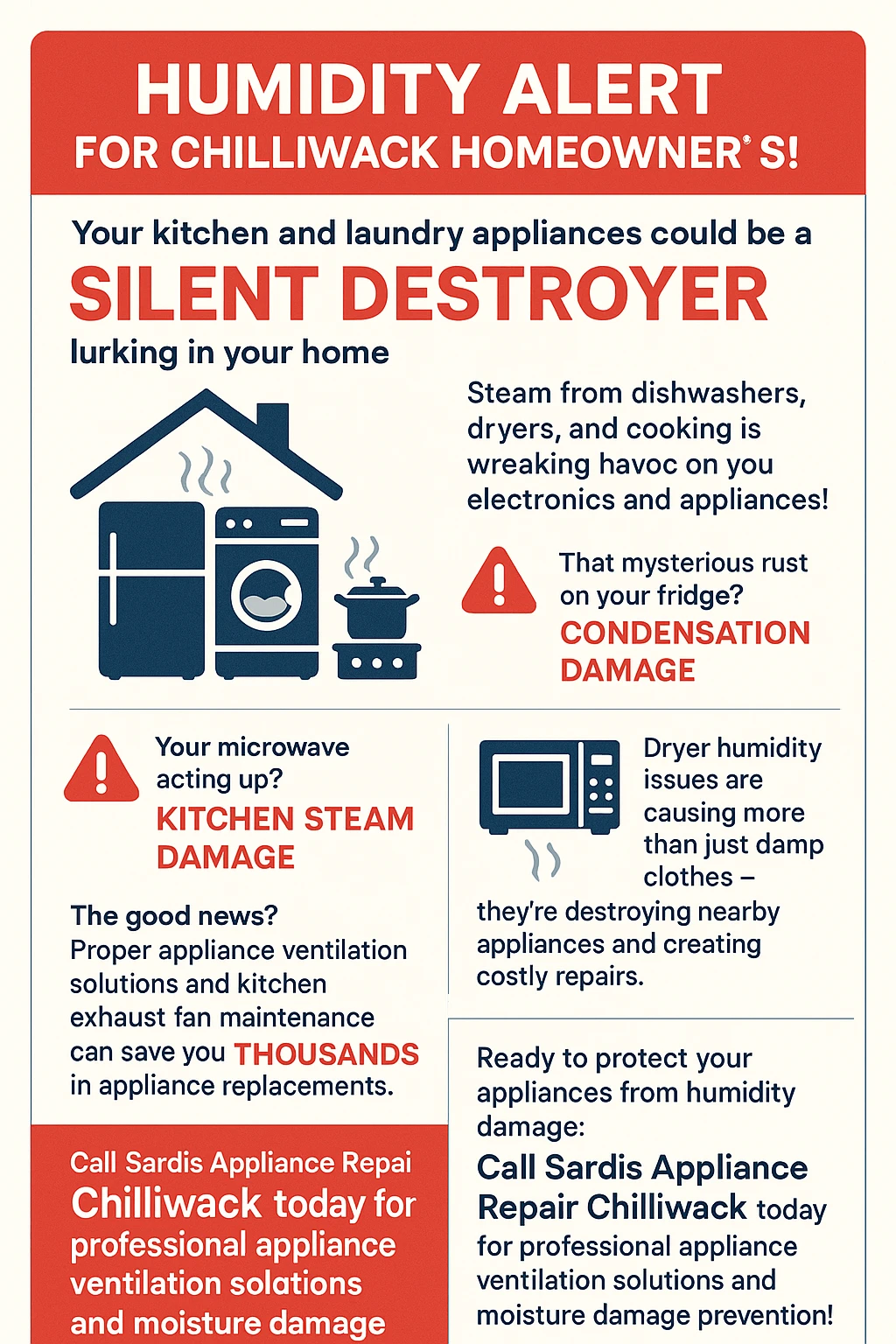

- Kitchen steam from dishwashers, microwaves, and cooking appliances causes premature cabinet damage and nearby electronics failures through moisture infiltration and corrosion

- Laundry room humidity from dryers and washing machines creates condensation that damages electronic control panels and promotes rust in metal components

- Proper ventilation systems and humidity control can extend appliance lifespans by 3-5 years while preventing costly moisture-related repairs

- Chilliwack’s Fraser Valley climate creates unique humidity challenges that require specialized moisture management strategies beyond standard manufacturer recommendations

- Professional humidity monitoring and control systems represent cost-effective investments compared to frequent appliance repairs and premature replacements

Understanding the Hidden Threat: How Humidity Destroys Home Appliances

The science behind humidity-induced appliance damage reveals a complex web of interconnected failure mechanisms that work together to systematically compromise your valuable home equipment. When moisture levels in your home exceed optimal ranges, a cascade of destructive processes begins that affects everything from delicate electronic circuits to robust mechanical components. The insidious nature of this damage makes it particularly dangerous because symptoms often appear gradually, masquerading as normal wear and tear until major component failures occur.Humidity can cause major electrical issues inside homes, with high moisture content affecting electrical equipment and wiring in ways that compromise safety and performance. Electronic devices become particularly vulnerable when humidity levels exceed 50%, as this threshold marks the point where condensation formation becomes likely when warm air contacts the cold surfaces commonly found within appliance housings. The moisture doesn’t need to be visible to cause damage; even microscopic water droplets can create electrical pathways that disrupt normal component operation.The electronic control systems that manage modern appliances represent the most vulnerable components in your home’s equipment lineup. These sophisticated circuits depend on precise electrical characteristics that humidity dramatically alters through several mechanisms. Water vapor infiltrates control boards and sensor assemblies, where it can cause immediate malfunctions through short-circuiting or create long-term degradation through electrochemical processes that gradually move metallic ions within semiconductor junctions. The combination of Chilliwack’s humidity with temperature changes creates expansion and contraction cycles that crack solder joints and loosen connections over time.Corrosion and rust development in metal components follows predictable patterns that accelerate dramatically in high-humidity environments. Even small amounts of moisture can conduct electricity, causing power shortages, while metal parts critical to electronic devices corrode and rust, leading to gradual performance weakening and eventual malfunction. The process begins with microscopic pitting on metal surfaces, then progresses to visible rust formation, and eventually compromises structural integrity. This progression explains why appliances that seem fine one day suddenly experience catastrophic failures the next.Understanding moisture infiltration pathways helps homeowners identify vulnerable areas where prevention strategies can be most effective. Humidity emanates from typical activities such as cooking, drying clothes, and washing dishes, with heating and cooling appliances contributing additional moisture loads that affect switchgear and electronic components. The moisture enters appliances through ventilation openings, around door seals, and through microscopic gaps in housing materials, then condenses on internal components where it begins its destructive work.

Kitchen Steam Damage: The Silent Appliance Killer

The kitchen environment presents the most challenging humidity conditions in most homes, where multiple appliances generate steam simultaneously while confined spaces prevent adequate moisture dispersal. Understanding how different kitchen appliances contribute to humidity problems helps homeowners implement targeted protection strategies that address the specific moisture sources threatening their valuable equipment investments.Dishwasher steam venting represents one of the most common sources of localized humidity damage in modern kitchens. Some dishwasher brands feature side vents in the door that release significant amounts of steam during operation and cause cabinet damage if the dishwasher isn’t installed properly. These dishwashers require installation that positions them proud or forward from the cabinetry so the vent openings aren’t covered or blocked. When improperly installed, the released steam concentrates against cabinet surfaces where it causes warping, discoloration, and premature finish failure.  A dishwasher moisture deflector provides a simple and effective solution for protecting countertops and cabinets from steam damage by redirecting the released moisture away from vulnerable surfaces. These deflectors work by creating a barrier that channels steam downward or outward, preventing the concentration of hot, moist air against wood surfaces. The investment in proper deflection systems typically pays for itself within months by preventing cabinet refinishing or replacement costs that can reach thousands of dollars.Over-the-range microwave installations create particular ventilation challenges that many homeowners don’t recognize until damage appears. Top venting OTR microwaves feature small vents right on the top that release cooking moisture directly upward into overhead cabinets, while tilt-up venting models have vents that open to push steam upwards with even greater force. The released moisture remains on cabinets above and causes premature cabinet damage through repeated cycles of wetting and drying that stress wood fibers and finish materials.Countertop appliances present additional steam exposure risks because they’re often positioned directly below overhanging wall cabinets where moisture has nowhere to escape. Coffee makers, toaster ovens, pressure cookers, rice cookers, and electric kettles all contribute heat and steam damage to cabinets through normal operation. Steam from appliances can result in steam-burn damage, which appears as a white film that develops on wood surfaces, while melamine and thermofoil cabinetry can begin to melt or delaminate when exposed to concentrated steam over time.Refrigerator condensation problems compound kitchen humidity issues by adding moisture to the air while simultaneously struggling to maintain proper internal temperatures. High ambient temperatures or high relative humidity cause excessive moisture, frost, or condensation in refrigerators, particularly when doors are left open for extended periods. Dense humidity from regional climate conditions causes refrigerators to work harder as moisture infiltrates cooling compartments, forcing compressor systems to cycle more frequently and generating additional heat that contributes to overall kitchen humidity levels.The cumulative effect of multiple steam sources operating simultaneously creates humidity spikes that exceed the natural ventilation capacity of most kitchens. During peak cooking periods, humidity levels can double or triple within minutes, creating conditions that promote condensation on cold surfaces throughout the kitchen. This condensation doesn’t limit itself to visible surfaces; it also forms inside appliance housings, electrical panels, and ventilation systems where it begins the long-term damage processes that eventually result in component failures and expensive repair bills.

A dishwasher moisture deflector provides a simple and effective solution for protecting countertops and cabinets from steam damage by redirecting the released moisture away from vulnerable surfaces. These deflectors work by creating a barrier that channels steam downward or outward, preventing the concentration of hot, moist air against wood surfaces. The investment in proper deflection systems typically pays for itself within months by preventing cabinet refinishing or replacement costs that can reach thousands of dollars.Over-the-range microwave installations create particular ventilation challenges that many homeowners don’t recognize until damage appears. Top venting OTR microwaves feature small vents right on the top that release cooking moisture directly upward into overhead cabinets, while tilt-up venting models have vents that open to push steam upwards with even greater force. The released moisture remains on cabinets above and causes premature cabinet damage through repeated cycles of wetting and drying that stress wood fibers and finish materials.Countertop appliances present additional steam exposure risks because they’re often positioned directly below overhanging wall cabinets where moisture has nowhere to escape. Coffee makers, toaster ovens, pressure cookers, rice cookers, and electric kettles all contribute heat and steam damage to cabinets through normal operation. Steam from appliances can result in steam-burn damage, which appears as a white film that develops on wood surfaces, while melamine and thermofoil cabinetry can begin to melt or delaminate when exposed to concentrated steam over time.Refrigerator condensation problems compound kitchen humidity issues by adding moisture to the air while simultaneously struggling to maintain proper internal temperatures. High ambient temperatures or high relative humidity cause excessive moisture, frost, or condensation in refrigerators, particularly when doors are left open for extended periods. Dense humidity from regional climate conditions causes refrigerators to work harder as moisture infiltrates cooling compartments, forcing compressor systems to cycle more frequently and generating additional heat that contributes to overall kitchen humidity levels.The cumulative effect of multiple steam sources operating simultaneously creates humidity spikes that exceed the natural ventilation capacity of most kitchens. During peak cooking periods, humidity levels can double or triple within minutes, creating conditions that promote condensation on cold surfaces throughout the kitchen. This condensation doesn’t limit itself to visible surfaces; it also forms inside appliance housings, electrical panels, and ventilation systems where it begins the long-term damage processes that eventually result in component failures and expensive repair bills.

Laundry Room Moisture Crisis: When Humidity Attacks Your Appliances

Laundry rooms represent ground zero in the battle against household humidity, where the combination of hot water, heated drying cycles, and often inadequate ventilation creates perfect conditions** RETURN A TOTAL OF 3 IMAGE PROMPTS AND THE BLOG WITH THEIR PLACEHOLDERS.* DO NOT USE /n or CHARACTERS **

Laundry rooms represent ground zero in the battle against household humidity, where the combination of hot water, heated drying cycles, and often inadequate ventilation creates perfect conditions** RETURN A TOTAL OF 3 IMAGE PROMPTS AND THE BLOG WITH THEIR PLACEHOLDERS.* DO NOT USE /n or CHARACTERS **

(604) 305-2992

(604) 305-2992

Schedule An Appointment

Schedule An Appointment