Ever wondered why your kitchen seems cursed during the holidays, with appliances failing just when you need them most? The truth is, your refrigerator, oven, and dishwasher aren’t conspiring against your holiday plans – they’re simply buckling under the perfect storm of overuse, electrical stress, and delayed maintenance that hits every December.

Picture this nightmare scenario that plays out in Chiliwack homes every holiday season: you wake up Christmas morning to discover your refrigerator has stopped cooling, last night’s dishes are still caked on plates because the dishwasher decided to quit mid-cycle, and your perfectly planned turkey dinner is in jeopardy because the oven won’t heat past 200 degrees. What feels like cosmic bad luck is actually the predictable result of multiple stress factors converging during the most demanding time of year for your household appliances. Modern kitchens packed with sophisticated electronics face unprecedented challenges when holiday entertaining pushes every system beyond its normal operating limits.

The phenomenon isn’t limited to older appliances either – brand new, expensive units fail just as dramatically when subjected to the relentless demands of holiday cooking and entertaining. Understanding why this happens, recognizing the warning signs, and implementing a strategic prevention plan can save Chiliwack hosts thousands of dollars in emergency repairs while ensuring their celebrations go off without a hitch. The key lies in recognizing that holiday appliance failures stem from predictable patterns of stress, electrical overload, and component fatigue rather than random mechanical problems.

From the Fraser Valley’s unique seasonal challenges to the specific vulnerabilities of modern appliances, this comprehensive guide reveals why your kitchen becomes a disaster zone during family gatherings and provides the emergency prevention strategies every smart host needs to protect their investment and their sanity during the holiday season.

Key Outtakes:

- Holiday appliance failures result from simultaneous stress on aging units designed for normal use, not peak entertaining demands that can triple typical usage patterns

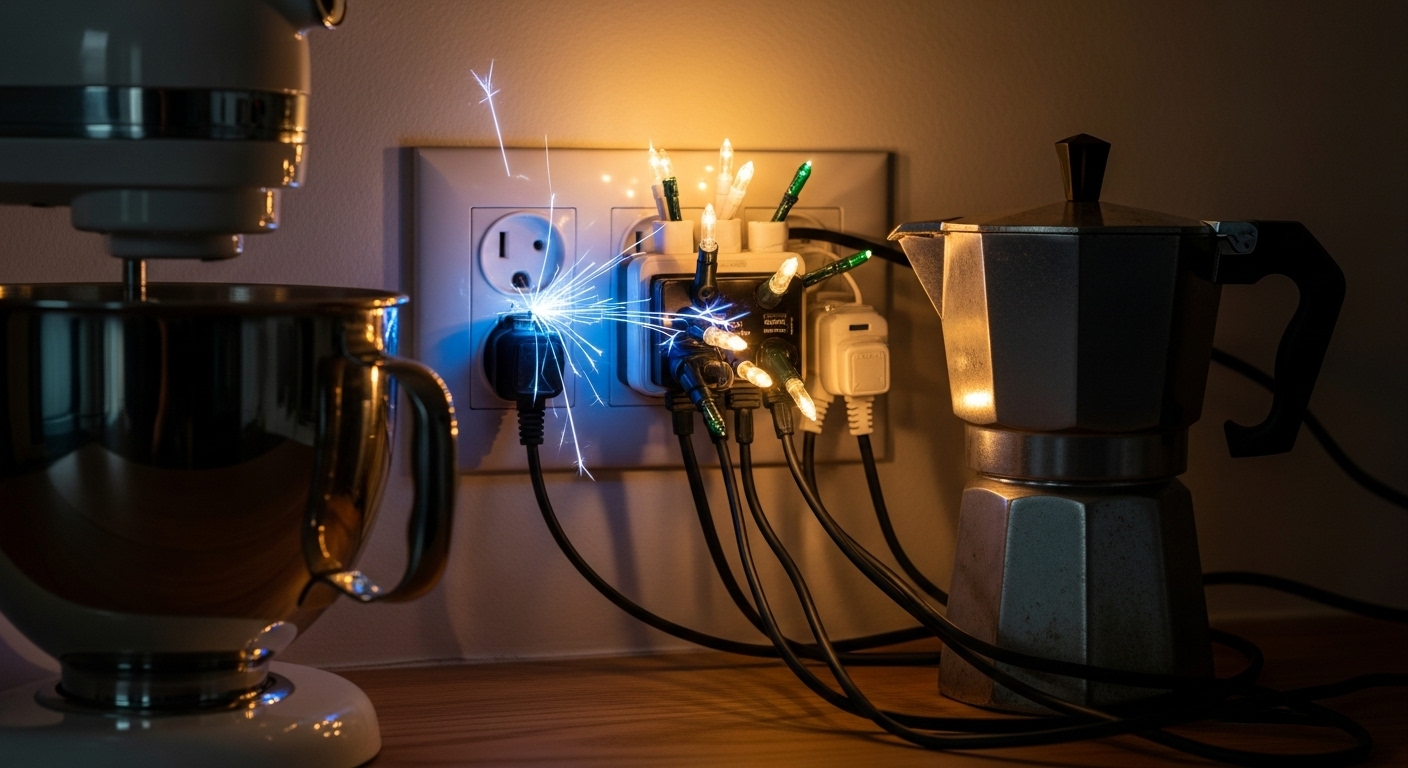

- Electrical system overload creates cascade failures affecting multiple appliances from a single electrical event, explaining why your fridge, dishwasher, and range might all fail simultaneously

- Modern appliances have significantly shorter lifespans than older models due to cheaper manufacturing and complex electronics, with refrigerators now lasting 7-10 years versus 19 years just fifteen years ago

- Pre-holiday maintenance and electrical assessment can prevent eighty percent of common failures through simple steps like cleaning condenser coils and testing systems before guests arrive

- Emergency preparedness including backup cooking methods and local Chiliwack service contacts creates resilience during crises when professional repair booking extends to multi-week waits

The Science Behind Holiday Appliance Disasters

The fundamental reason appliances break during holidays involves understanding that continuous operation under maximum capacity degrades mechanical and electrical components in ways that would never occur during normal use periods. Your oven typically operates for perhaps ten to fifteen hours total during an average month, cycling on and off for meal preparation. During holiday season, that same oven might run continuously for eight to twelve hours in a single day as you prepare multiple dishes, bake endless batches of cookies, and roast holiday centerpieces. This extended thermal cycling forces heating elements through repeated expansion and contraction phases that stress internal wiring and degrade components designed for intermittent use.

Refrigerators face equally dramatic stress when packed to capacity with holiday food purchases, guest beverages, and prepared dishes stacked on every available surface. The compressor that normally cycles on and off throughout the day maintaining steady temperature now runs continuously, fighting against blocked air vents caused by overstuffed shelves and constantly opening doors as guests retrieve drinks and snacks. This continuous operation generates excessive heat that damages internal components while simultaneously reducing the refrigerator’s ability to maintain safe food temperatures.

Dishwashers experience perhaps the most dramatic usage spike, running two or three complete cycles daily instead of their normal once-per-day operation. The pump motors, spray arms, and drainage systems that handle a typical family’s dishes suddenly process the debris load from large dinner parties, numerous guests, and constant meal preparation. One local appliance maintenance expert documented that dishwasher service calls increase by over 200% during the six weeks surrounding major holidays, with clogged filters and drainage failures representing the most common emergency repairs.

The interconnected stress creates a domino effect where one appliance’s increased demand affects the entire kitchen ecosystem. When your oven runs for twelve straight hours, it generates ambient heat that forces your refrigerator to work harder. When your dishwasher cycles multiple times daily, it adds humidity and heat to the kitchen environment while drawing hot water that impacts your water heater’s capacity. This compound stress explains why multiple appliances often fail within days of each other during holiday periods – they’re all operating under conditions far exceeding their design specifications.

The Modern Appliance Durability Crisis

Today’s sophisticated appliances represent a paradox where higher prices and more advanced features correlate with dramatically shorter lifespans and higher failure rates compared to appliances manufactured just decades ago. Industry data reveals that refrigerators purchased fifteen years ago carried expected lifespans of nineteen years, while new refrigerators today are estimated to last only seven to ten years depending on the model. This durability decline reflects fundamental changes in manufacturing philosophy where companies prioritize hitting specific retail price points rather than engineering for longevity or reliability.

The transition from mechanical components to computerized control systems has created exponentially more failure points in modern appliances. Your grandmother’s 1950s refrigerator operated with simple mechanical thermostats, basic compressors, and manual defrost cycles that could function for decades without service. Today’s smart refrigerators contain sophisticated logic boards, digital temperature displays, computerized defrost cycles, and integrated water and ice dispensers – each representing potential failure points that can render the entire appliance inoperable when they malfunction.

Manufacturing location changes compound reliability problems as appliance brands undergo ownership transitions that prioritize cost reduction over quality maintenance. One appliance repair professional documented how Kenmore appliances maintained excellent reliability when manufactured by established American companies like Whirlpool and Frigidaire, but successive manufacturing transitions to LG, Samsung, Haier, and now Daewoo have resulted in progressively declining reliability with each change. This means the brand name provides less indication of quality than the specific manufacturing origin and production year.

Logic board placement represents a particularly problematic design decision where manufacturers install expensive computerized control systems directly above oven heat sources or in other high-temperature locations. These circuit boards, which can cost several hundred dollars to replace, fail prematurely from thermal stress in environments they were never designed to withstand. When a logic board fails, the entire appliance becomes inoperable despite all mechanical components functioning perfectly, and replacement parts may become unavailable within just a few years as manufacturers discontinue support for older models.

In-door water and ice dispensers, while convenient features that consumers appreciate, represent major failure points in modern refrigerators. The complex water line routing, electronic valves, and integrated electronics required for these systems create multiple opportunities for malfunction. Industry service data indicates that water and ice dispenser problems rank among the most common reasons refrigerators require professional repair, with repair costs often approaching forty to fifty percent of the appliance’s original purchase price.

Electrical System Cascade Failures During Peak Demand

Understanding electrical system vulnerabilities becomes critical when examining why multiple appliances often fail simultaneously during holiday periods – a phenomenon repair professionals call the “appliance trifecta crisis.” When your refrigerator, dishwasher, and range all stop working on the same day, the cause typically involves a single electrical system problem rather than three coincidental individual appliance failures. Modern appliances packed with sensitive electronic control systems operate within narrow voltage tolerances and fail catastrophically when electrical disturbances exceed their design parameters.

Holiday electrical demand spikes from multiple sources converging simultaneously in ways that stress aging residential electrical systems beyond their capacity. Oven usage increases dramatically, consuming approximately fifty-eight kilowatt hours during peak holiday months compared to much lower baseline consumption during normal periods. Dishwashers add thirty kilowatt hours monthly during heavy entertaining periods. Holiday lighting displays consume enormous electricity loads, with traditional incandescent setups using up to 1,300 kilowatt hours over a month. Multiple guests create additional electrical demand through phone charging, hair dryer use, extensive hot water consumption, and space heaters providing warmth in areas not normally heated during other seasons.

(604) 305-2992

(604) 305-2992

Schedule An Appointment

Schedule An Appointment